visit the

Factory

It is in our workshop, located in the south of the Vosges, that all our products are designed and manufactured. From the raw material to the finished products, each step is made here. This control of the process ensures us quality and reactivity.

By combining traditional techniques and new technologies, we have created modern and authentic products.

Visit of the workshop

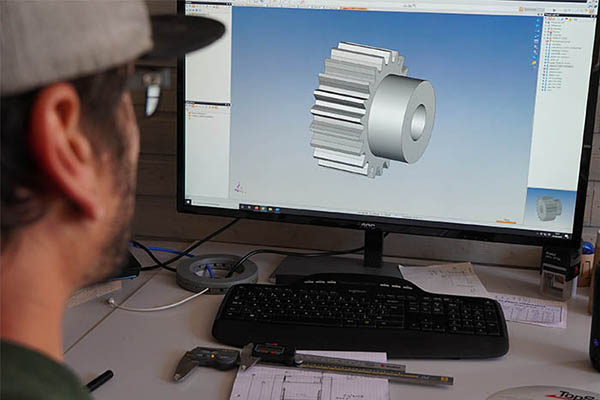

Design office

As an example of the engineer-craftsman, we have created a company that connects the head and the hands. Imagined and modeled, the future creations are then prototyped before being entirely manufactured in our workshop.

Production management

While Kevin oversees the progress of manufacturing, Jeremy makes sure that nothing is missing from the workshop.

CAD & CAM

A Computer Aided Design software allows us to model the products in 3D. This allows us to test their operation and even control the manufacturing process on the numerically controlled milling machine.

Material resistance

This is where the products are designed and developed. Different compositions of wood, fibers and glues are tested to obtain the best mechanical characteristics.

Since 2013, we have been continuously developing our knowledge of natural materials and bio-composites.

Bonding & Bio-Composites

Our goal: to reveal the potential of natural materials. By combining wood, bamboo and linen fiber, we create products that are as surprising as they are effective.

Adhesives

Depending on the characteristics required, we use different types of adhesives. A hood allows us to work in good conditions.

Natural fiber reinforcement

To reinforce our products, we do not use fiberglass but linen. This natural fiber reveals amazing properties: it is resistant, light and absorbs vibrations.

Pressing

We design and produce all our molds using digital control. They are composed of a male and a female part. They are the ones that give the shape to the products.

The molds are placed in the presses. The presses can exert more than 50 tons of pressure. This results in an extremely strong bond.

Traditional & Digital

Traditional and digital machines coexist.

Valuing manual know-how while constantly evolving: this is our credo!

Traditional eyewear

It is important to us to preserve the manual know-how.

The faces of the glasses are cut by hand on traditional eyewear machines. Simple and efficient, they never break down.

5-axis CNC

At the same time, a digital milling machine allows us to work on complex shapes such as molds, skates and eyeglass temples.

The design made on the computer is then executed by the machine. The parts are held by vacuum on the table while the head machines the wood to the desired shape.

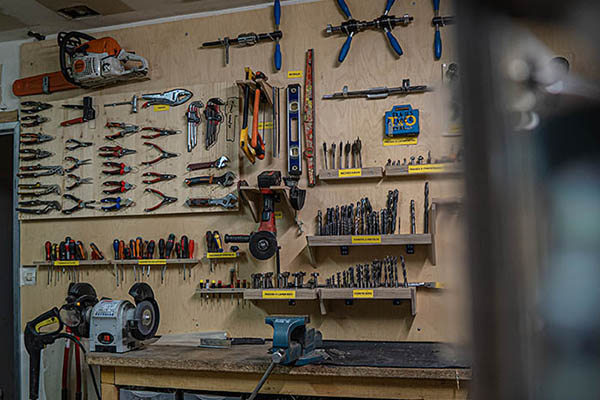

Metal work

This is the toolbox of the workshop. Here we build or repair the machines of the workshop.

Pipo drills, bends, turns and welds metal like no other.

Multi-Skills

L'Atelier is a real Swiss Army knife. Over the years, we have integrated new skills to be more and more autonomous.

Laser CN

From a computer drawing, three laser machines will cut and engrave the wood.

Thanks to their speed and precision, they allow the marking of glasses, skates, and the manufacturing of small parts.

Screen printing

This traditional printing method is used for the marking of skates and our displays.

Like a stamp, a screen lets the ink pass through to the desired areas. Perfect for printing on wood.

Finishing booth

We have developed an expertise in finishing methods. Depending on the needs, we use different types of oils or varnishes.

The suction wall of the booth allows to apply the varnish with a spray gun in the best conditions.

Assembly & Shipping

To limit our stocks as much as possible, all our products are made to order. An eyewear is manufactured and sent in less than 4 days.

Custom manufacturing

To limit stocks, our production is made only to order. This method allows us to rationalize our costs and to propose thousands of references for a product almost made to measure.

Custom-made

For your glasses, for example, you can choose from 40 shapes in 2 sizes, 20 finishes, 3 types of temples and optical or solar lenses. This represents nearly 10,000 possible variations.

As for the bikes, they are entirely made on measure.

Shipments

You will find boxes, catalogs, posters, displays and especially products made with love that are waiting for you.

All the products go through it: packed and weighed, they are sent to the four corners of France.

A Break Is Needed

We spend a lot of our time at work. We might as well make it fun.

Kitchen

At 10 am, it's the queue in front of the coffee maker... and at 12 pm, it's the microwave war! While Robin works in the garden, Felix takes a nap in the sun.

In the open air

On the commune of Les Voivres (300 inhabitants) our workshop faces the forest. Located in the middle of the fields, the small artisanal zone knows neither the traffic jams, nor the pollution.

The ramp

Essential for any self-respecting skateboard manufacturer, our ramp allows us to stretch our wheels.