Manufacturing of

Wooden Glasses

Fabrication des

Lunettes bois

The manufacture of a frame requires many steps and great dexterity. Each of our craftsmen makes your frames from A to Z. They know all the machines and master each gesture.

Discover The Manufacturing

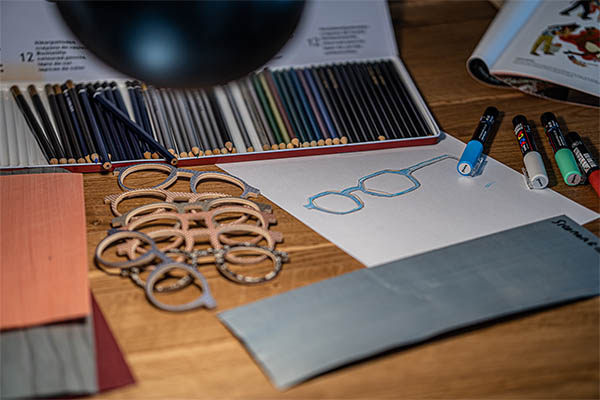

Drawings & Creations

The birth of an eyewear starts with a design. For each shape, dozens of prototypes are made to ensure comfort and look. You can then choose from 6 ranges. Each explores an original way of working with wood: smoked, stained, shredded or even printed, the choice is yours.

Shapes

The collection is composed of 40 models, available in 2 sizes. Designed by computer, dozens of prototypes are made to obtain the best compromise between thinness, resistance and comfort.

Ranges

Each range explores a specific woodworking technique, a unique way of working with wood. Torrefied, stained, chipped or even printed, the rendering will be completely different from one finish to another.

Dark or colored species are the easiest to wear.

Woods

We use local woods such as oak and maple. The thin sheets of wood of 0.5 mm thickness are obtained by slicing. Living material, the color varies slightly from one frame to another and a certain patina may appear over time.

The Face

As wood engineers, we have designed the frames to be durable and comfortable. Made of 9 sheets of wood, our glasses are handcrafted with traditional machines.

Structural bonding

Nine sheets of veneer are glued and pressed into a mold. The wood will keep its shape, will be more resistant and more flexible. This allows us to mount glasses with a high correction without opening the frame.

Traditional machining

The machining is done by hand on traditional eyewear machines. Templates are used to cut out the eyes on the router and the outline on the pantograph. The holes and the groove in which the glass is inserted are then made.

Nose pads

The nose pads provide a good contact surface and slightly distance the frame from the face. This way the glasses do not slip and the eye is at a good distance from the lens. Among the two sizes, you will find a frame that fits your nose.

The Temples

Having a beautiful Made In France eyewear is good. Having a nice eyewear is better! We combine the two with our temples that ensure support and comfort. Available in two sizes, or in metal, they adapt to your morphology and your desires.

Curvature

The temples are glued so that they taper from 7 to 5 layers at the ear. The ergonomic shape of the spatula curves outward to avoid a compression point.

Comfortable

Available in two lengths, the temples ensure that the frame is held in place. The curvature allows the frame to rest on the cranial rock, the bony area behind the ear.

CNC machining

A 5-axis machining center assists the craftsmen in certain steps of the eyewear manufacturing process. Whether it is manual sanding or the use of state-of-the-art machines, the entire team is versatile.

Metal temples

As an option you can choose metal temples, made in the Jura. Easy to adjust, they will give a modern style and a light feeling to your frame.

Finishing touches

Making a frame takes time and involves many steps. Our craftsmen master each of them for a quality product.

Sanding

Each spectacle is sanded by hand. Particular care is given to areas of contact with the skin such as the nose and temples. This results in a soft and comfortable frame.

Laser

A laser machine engraves the frame reference. The beam lightly burns the wood and leaves a discreet and indelible mark. Get out your magnifying glasses.

Varnishing and polishing

A thin layer of 100% hypoallergenic varnish is applied to protect them from perspiration and humidity. Finally, a manual polishing on cotton flannels ensures softness and comfort.

Assembly & Adjustment

To limit our stocks as much as possible, all our products are made to order. An eyewear is manufactured and sent in less than 4 days.

Flex hinges

We chose double barrel flex hinges. Strong and durable, they exert a slight compression of the temples on the skull to ensure the frame stays in place.

Assembly

Assembled with screws, the hinges are securely fastened and can easily be replaced. In case of a problem, it is not necessary to change the entire frame. The hinges can be removed to allow the frame to be recycled.

Dressing

With the help of pliers, it is possible to slightly deform the hinge leg. The distance between the temples and the pantoscopic angle can thus be adjusted. The glasses are adjusted to ensure that the temples are straight and parallel.

Partner Opticians

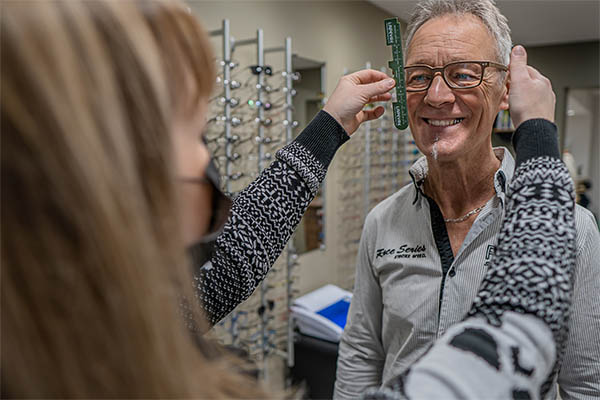

The opticians carry out the final stages of manufacturing your glasses. After advising you on the choice of your frame, they take the necessary measurements to cut the lenses and ensure the best visual comfort.

Our partner opticians are selected for their know-how. Used to working with our frames, they are the only ones authorized to sell them.

Advice and dimensioning

Depending on your morphology and your correction, he will advise you in the choice of the frame. If the model is not in stock, he can order it in less than a week.

Trimming

A machine measures the shape of the frame and cuts the lens. Our partner opticians are used to working with our frames. It is quite possible to mount lenses with important corrections.

Mounting

All that remains is to adjust the frame to your face so that it does not slip and is as comfortable as possible. To clean them, use a damp, slightly soapy wipe.

It is important to keep in mind that wood is a living material and that a certain patina will appear over time.

Adjustment

With the help of pliers, the optician can adjust the angle of the hinge, allowing the frame to fit all faces.

If your temples are out of place or your glasses are slipping, your optician can easily adjust them.

Our partners

Looking for a gueule de bois ?

Let a professional advise you and be surprised by the comfort of our frames.